Professional Liquid Filling Machine Manufacturer Liquid Filling Machine Manufacturer Company

Product details of the liquid filling machine manufacturer

Product Information

Using high-quality raw materials, SKYM liquid filling machine manufacturer has a fine appearance. As the stringent quality tests run through the whole production process, the quality of the product can be thoroughly assured. Zhangjiagang Sky Machine Co., Ltd. has great product and talented staff.

Applicable bottles

Features

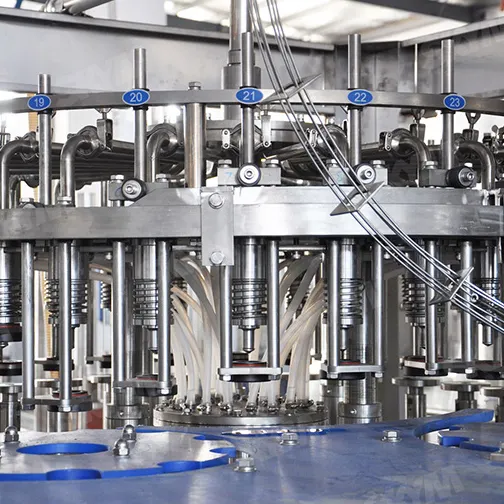

BGF-series rinsing, filling, Capping 3-in-1 monobloc machine introduced by foreign advanced gas-filling technique is a high performance fully automatic liquid packaging equipment. Machine for carbonated beverage packaging machine has the following characteristics: filling tank, filling valves and other components in direct contact with the material are high-quality stainless steel or non-toxic materials, in line with food hygiene requirements: use of resistant seals hot rubber to meet the high-temperature sterilization process of user requirements: PCL programmable controller used to realize from the bottle into the machine to the packaging of finished using the automatic control of frequency control, easy to transfer the user to adjust prepared to meet the different process on the capacity requirements; using isobaric filling principle and popular spring-loaded valves, ensuring the quality of the beverage, using an advanced magnetic clutch adjustment screw cap torque device to ensure the quality of the blocks.

Washing Part

Function : washing bottle inside and outside dust .

1.All 304/316stainless steel rinse heads, water spray style inject design, more save water consumption and more clean

2.304/316 Stainless steel Gripper with plastic pad, ensure minimal bottle crash during washing

3. 304/316 stainless steel washing pump

Filling Part

Fucntion : filling wine into bottle .

1. 304/316 Stainless steel high precision filling nozzle

2. Filling volume adjustable in fine rank, same liquid level after filling

3. All 304/316 stainless steel contact parts & liquid tank, fine polish, no death corner, easy to clean

4.304/316 stainless steel filling pump

Capping Part

Function : put caps on bottle.

<1. Place and capping system, electromagnetic capping heads, with burden discharge function, make sure minimum bottle crash during capping <2> All 304/316 stainless steel construction

3. No bottle no capping

4. Automatic stop when lack of bottle

Device parameters

|

Model |

BGF14-12-5 |

BGF16-16-5 |

BGF24-24-8 |

BGF32-32-10 |

BGF40-40-12 |

|

Capacity(BPH) |

2500 |

3000 |

5000 |

8000 |

10000 |

|

Suitable to Bottle Shape |

50-120H=160-320 |

||||

|

Power Supply(KW) |

2.02 |

2.42 |

3.12 |

3.92 |

3.92 |

|

Overall dimension(L*W*H) |

2400*1770*2700 |

2800*2060*2700 |

2950*2230*2700 |

3700*2650*2700 |

4850*3320*2700 |

Company Advantage

• SKYM Filling Machine strives to open up domestic and international markets. Industrial Machinery/Packaging Machines/Filling Machines,Water filling machine、Oil filling machine are sold to various countries and regions around the world. They are well recognized by consumers.

• SKYM Filling Machine's location has a pleasant climate, abundant resources, and unique geographical advantages. Meanwhile, the traffic convenience is conducive to the circulation and transportation of products.

• After years of sincerity-based management, SKYM Filling Machine runs an integrated business setup based on the combination of E-commerce and traditional trade. The service network covers the whole country. This enables us to sincerely provide each consumer with professional services.

SKYM Filling Machine's tools are excellent in quality and favorable in price with high cost performance. And if you have any needs, please call us.