Automatic Wine Filling Machine Vendor

Product details of the automatic wine filling machine

Quick Detail

SKYM automatic wine filling machine is produced under the international production standards. Strict quality control is conducted by professionals to ensure the product is always at the best quality. Zhangjiagang Sky Machine Co., Ltd. has established long-term relationships with many customers.

Product Description

Compared with similar products, the automatic wine filling machine of SKYM Filling Machine is more strict in the selection of raw materials. The specific aspects are as follows.

Applicable bottles

Features

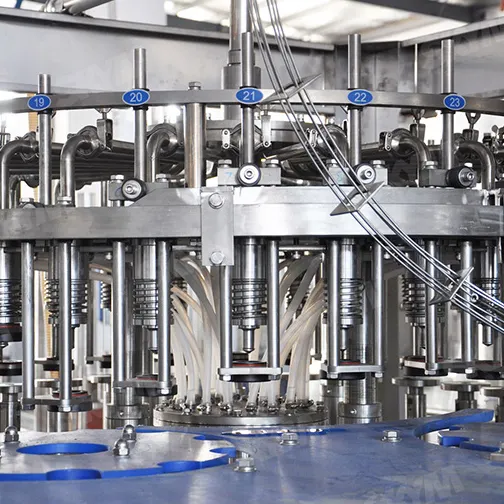

BGF-series rinsing, filling, Capping 3-in-1 monobloc machine introduced by foreign advanced gas-filling technique is a high performance fully automatic liquid packaging equipment. Machine for carbonated beverage packaging machine has the following characteristics: filling tank, filling valves and other components in direct contact with the material are high-quality stainless steel or non-toxic materials, in line with food hygiene requirements: use of resistant seals hot rubber to meet the high-temperature sterilization process of user requirements: PCL programmable controller used to realize from the bottle into the machine to the packaging of finished using the automatic control of frequency control, easy to transfer the user to adjust prepared to meet the different process on the capacity requirements; using isobaric filling principle and popular spring-loaded valves, ensuring the quality of the beverage, using an advanced magnetic clutch adjustment screw cap torque device to ensure the quality of the blocks.

Washing Part

Function : washing bottle inside and outside dust .

1.All 304/316stainless steel rinse heads, water spray style inject design, more save water consumption and more clean

2.304/316 Stainless steel Gripper with plastic pad, ensure minimal bottle crash during washing

3. 304/316 stainless steel washing pump

Filling Part

Fucntion : filling wine into bottle .

1. 304/316 Stainless steel high precision filling nozzle

2. Filling volume adjustable in fine rank, same liquid level after filling

3. All 304/316 stainless steel contact parts & liquid tank, fine polish, no death corner, easy to clean

4.304/316 stainless steel filling pump

Capping Part

Function : put caps on bottle.

<1. Place and capping system, electromagnetic capping heads, with burden discharge function, make sure minimum bottle crash during capping <2> All 304/316 stainless steel construction

3. No bottle no capping

4. Automatic stop when lack of bottle

Device parameters

|

Model |

BGF14-12-5 |

BGF16-16-5 |

BGF24-24-8 |

BGF32-32-10 |

BGF40-40-12 |

|

Capacity(BPH) |

2500 |

3000 |

5000 |

8000 |

10000 |

|

Suitable to Bottle Shape |

50-120H=160-320 |

||||

|

Power Supply(KW) |

2.02 |

2.42 |

3.12 |

3.92 |

3.92 |

|

Overall dimension(L*W*H) |

2400*1770*2700 |

2800*2060*2700 |

2950*2230*2700 |

3700*2650*2700 |

4850*3320*2700 |

Company Introduction

Zhangjiagang Sky Machine Co., Ltd. specializes in managing the business of high-quality Industrial Machinery/Packaging Machines/Filling Machines,Water filling machine、Oil filling machine. SKYM Filling Machine intends to be honest, efficient, cooperative and win-win in the business operation. We are committed to providing quality products and excellent services for the majority of customers. We have experienced production experts and technical teams. In order to provide products of good quality and reasonable price, our team members use advanced technology to improve quality and reduce the cost. We are willing to understand the real needs of our customers. Then, we will provide the best solutions to their needs.

We are willing to go hand in hand with you to create a better future.